Automate inspection tasks with computer vision

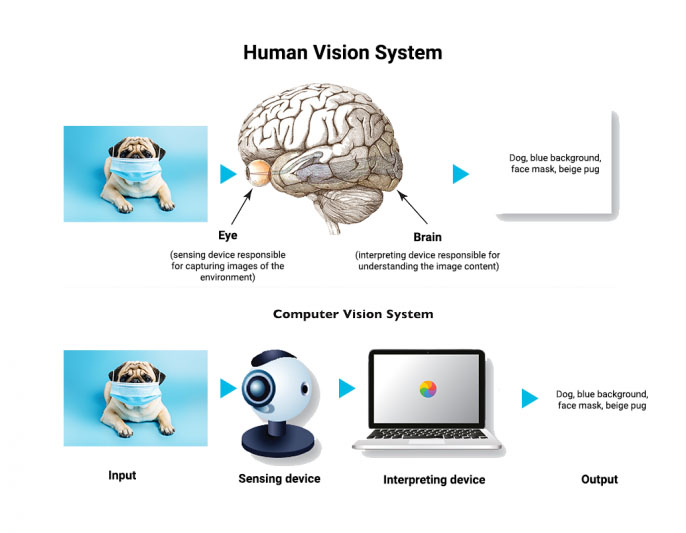

Our brain is a beautifully complex machine, with one look at a picture we can immediately describe all of the information that is visibly present. Have a look at the picture below.

If asked what the image is about, you would probably tell me there is a dog, more specific a beige pug, with a surgical face mask that lies on a blue background. It’s also probably related to the coronavirus as a concept of protection against the disease.

The day a computer will be able to get to this level of both precision and generality, has not come yet. But we are steadily closing the gap and there are already some practical use cases where computer vision proves highly valuable.

What is computer vision?

Computer vision is the field of computer science that focuses on creating digital systems that can process, analyze, and make sense of visual data (images or videos) in the same way that humans do. The concept of computer vision is based on teaching computers to process an image and understand it. As images and videos are a very specific kinds of data, AI computer vision techniques have evolved into a specific niche within machine learning. Technically, machines attempt to retrieve visual information, handle it, and interpret results through algorithms.

Different forms of computer vision

Here are a few common tasks that computer vision systems can be used for.

Object classification

The system parses visual content and classifies the object on a photo/video to the defined category. For example, the system can find our dog among all objects in the image. Just like we talked about in our previous blogpost.

Object classification has a very data-driven approach to classify images into distinct categories. Instead of trying to specify what every one of the image categories of interest looks like directly in code, we provide the computer with many examples of each image class and then develop learning algorithms that look at these examples and learn about the visual appearance of each class.

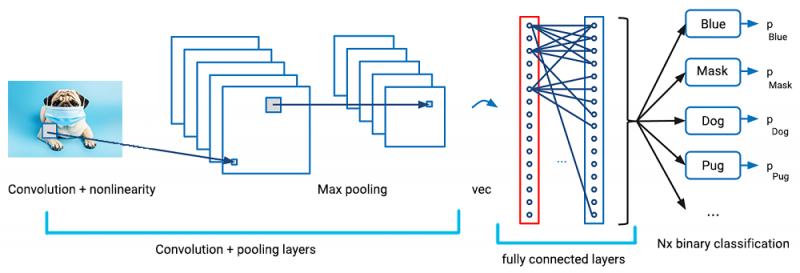

In a nutshell, we first accumulate a training dataset of labelled images, then feed it to the computer to process the data. The most popular architecture used for image classification is Convolutional Neural Networks (CNNs). A typical use case for CNNs is where you feed the network images and the network classifies the data.

Image classification with a CNN

Object classification is already incorporated in e.g. medical applications for purposes such as breast and skin cancer detection. These image detection techniques allow doctors to detect slight differences between cancerous and non-cancerous images. This allows them to work faster and produce more accurate diagnoses for the patient.

Many manufactures are now using it as an automatic quality control aid to increase overall consumer satisfaction. See our use case below for more information.

Object identification

The system parses visual content and identifies a particular object on a photo/video. For example, the system can find a face mask on the dog in the image.

The task to define objects within images usually involves outputting bounding boxes and labels for individual objects. This differs from the classification/localization task by applying classification and localization to many objects instead of just a single dominant object. You only have two classes of object classification, which means object bounding boxes and non-object bounding boxes. For example, in car detection, you have to detect all cars in a given image with their bounding boxes.

Image credit: Priya Dwivedi

ML2Grow has experience with this technique in parking lot occupancy detection or traffic flow analysis.

Object tracking

The system processes video finds the object (or objects) that match search criteria and track its movement.

This can be used for example to recognize patterns between human body movement and pose over multiple frames in video footage or real-time video streams. For example, our research has been used for tracking swimmers when they are moving through the water. Those video recordings can be used to quantitatively assess the athletes’ performance without manually annotate the body parts in each video frame.

Or in agriculture where we can automatically monitor crop growth. Object tracking allows to continuously and non-destructively monitor plant growth and the response to nutrient requirements.

This technology can also be used in retail as a means of tracking customers within a store. Strategically placed counting devices throughout a retail store can gather data about where customers spend their time, and for how long. This can be used to improve store layout optimization.

A social distancing detector using object tracking. Image credit: Basile Roth

How can we apply this technology to your business?

As you can see computer vision has now a massive impact on companies of all industries, from retail to agriculture. It is especially useful for problems where we would need a human’s eye to assess the situation.

Use Case

Let’s illustrate with a use case in how implementing our advanced machine learning helped them to tackle some of their most important issues.

A manufacturer based in Flanders was interested in implementing an automated quality inspection system into its production line.

The problem

The visual quality control of the manufactured goods happens by means of a control table controlled by an operator, which is without technical tools, visually detecting errors in the manufactured goods. This is going at a certain speed. The process roughly consists of the operator manually checking the original sample with the manufactured ones.

The customer wanted to modernize their machine park to boost the efficiency and speed of the control process. The adoption of our technology would allow them to further automate their production process.

Our solution

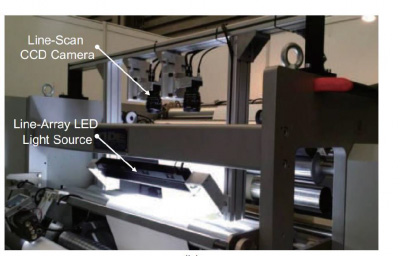

Our main goal is to take control of the project and fully unburden the customer for achieving the set goals. We will assess and install the most preferable camera and roll-out our AI solution to process the visual data. We create private secured data storage and cloud system for storing the data and develop a feedback system for the machine operator. Our job is also to train the employees with the new technology and use their feedback to perfect the system.

Example architecture of an AI model for the detection of flaws in a production line. Image credit: Shuang Mei, Yudan Wang, Chuan Wu

What are the benefits?

First of all, human operators would be aided by technological systems that will allow them to work more efficient and faster. It will also improve the activation of the operators and improve the working conditions by eliminating very repetitive tasks.

Computer vision brings intelligence to the quality control and monitoring process. A deep learning model analyses images of goods on the production line, using the knowledge gathered from training data that is based on the insights of expert labellers. This minimizes the quantity of goods products thrown out and bad products reaching the market.

In short, this will lower the number of returns from end consumers through more accurate and thorough control of the manufactured goods.

This video from BMW perfectly demonstrates what is possible with computer vision in production lines.

The results

The automated quality control process that we implemented for our customers now safeguards their brand reputation by minimizing faults in production lines and allows the operators to focus on more meaningful tasks and less repetitive work.

We deliver projects from A to Z, tailored to your needs.

Interested? Contact us now and take your business processes to the next level.